CIC Materials

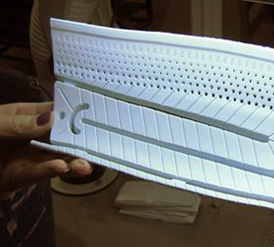

CIC has developed a unique and growing range of material qualities for most applications.

- Ceramic cores suitable for casting by Equiax, Directional Solidification and Single Crystal processes.

- Nickel, chrome & cobalt based, stainless steels, high temperature, aluminium.

- Exceptionally stable core bodies with very high tolerance.

- Dimensional control achieved through advanced green core reforming techniques.

- Core setters can be used for dimensional control if required.

- Range of shrinkages to suit customers’ existing tooling.

Below is a table showing our standard product mixes. Mixes can be varied to suit a customer's needs.

| Mix | Description | Use |

| CIC1 | Used for large land base type cores with good stability | Nickel-based equiax, DS (directional solidification) castings |

| CIC2 | High silica core material | Nickel-based equiax, DS alloys |

| CIC3 | Silica-based core material with high temperature stability | Nickel-based equiax, DS and SX (single crystal) castings |

| CIC4 | Silica-based core material with good high temperature stability | DS and SX castings |

| CIC5 | Silica-based core material with good high temperature stability. Particularly suited where hot tearing is a problem | Nickel-based equiax, DS and SX castings |

All products can be strengthened by one of two treatments that increase strength by a factor of up to 4 times.